Collection: Cement Boards

-

Routed Dry Screed Overlay Board with Turns

Regular price £25.83Regular price -

High-Performance Flat Dry Screed Overlay Cement Boards – Non-Routed for Underfloor Heating

Regular price £20.48Regular price -

ProTile20 – 20mm Cementitious Insulation Panel for Underfloor Heating & Tiled Floors

Regular price £10.76Regular price -

Joint Adhesive for Dry Screed Overlay Cement Boards for underfloor heating

Regular price £21.19Regular price -

6mm Tile Backer Board – High strength underfloor heating insulation

Regular price £5.95Regular price -

25mm Gypsum Fibre Structural Floor Panel | Load Bearing & UFH-Ready

Regular price £40.62Regular price -

18mm Gypsum Fibre Structural Floor Panel | Load Bearing & UFH-Ready

Regular price £31.32Regular price

Everything You Need to Know About Our ThermRite Cement Panels

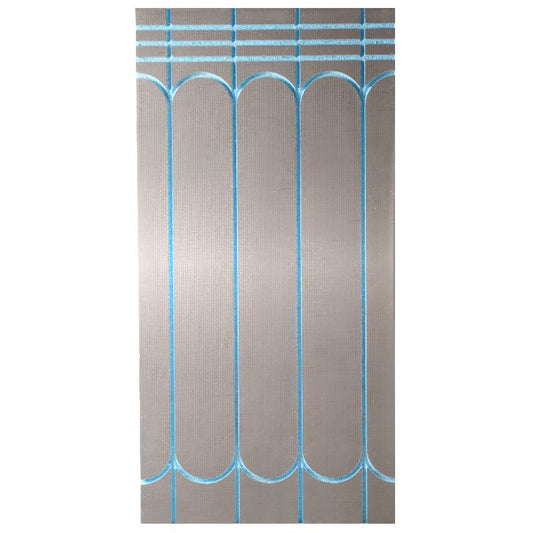

ThermRite High-Performance Flat Dry Screed Overlay Cement Board (Non-Routed, 18mm)

This 18mm flat cement-board overlay creates a strong, tile-ready surface directly over grooved insulation boards in underfloor-heating (UFH) systems. It features a low-profile design, tongue-and-groove interlocking edges (no screws required), high thermal conductivity, and low thermal resistance — ensuring efficient, even heat transfer and stable performance.

Because it's moisture-resistant and dimensionally stable (unlike chipboard), it’s a smart choice for wet areas and allows ceramic or porcelain tiles to be laid directly without additional substrates.

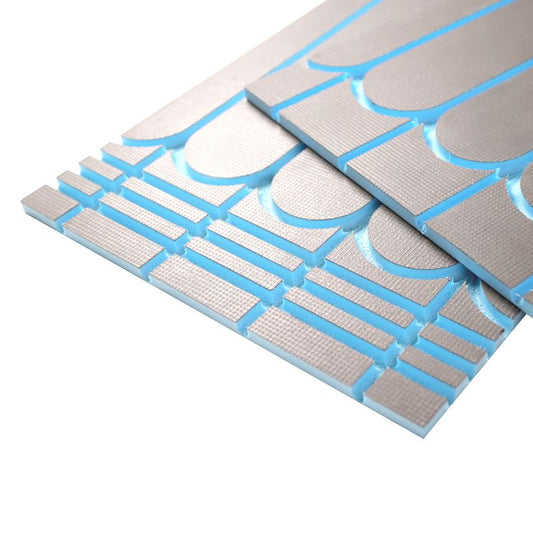

ThermRite Routed Dry Screed Overlay Cement Boards (Grooved) – 18 mm

These grooved cement boards are engineered to integrate directly with wet UFH pipework, allowing you to embed heating pipes before finishing the floor. The 18mm cement board offers a low build-up - whilst designed to support ceramic or stone floor finishes directly.

With carefully engineered grooves and integrated “runs and turns” in some panels, pipe installation becomes simpler and more secure, and the resulting floor offers excellent structural stability, tile-ready surface, and reliable heat distribution.

Cement Overlay Systems for Efficient & Durable Underfloor Heating Installations

ThermRite’s cement-based panels provide a stable, moisture-resistant, and heat-conductive base — ideal for finishing with ceramic tiles, porcelain, or stone directly after installation, without the need for bulky screed layers.

These boards excel in projects where thermal performance, low build-up height, and long-term durability matter most — such as bathrooms, kitchens, and other wet or high-traffic areas. The interlocking edge design, stable cementitious composition, and strong impact resistance combine to make them a dependable base for underfloor heating + tile applications.

Why ThermRite Cement Boards Are a Smart Choice for UFH + Tile Floors

Ready-to-tile surface: Cement boards accept ceramic/porcelain tiles directly, saving time and materials compared with screed + substrate + tile build-ups.

Low profile but strong: 18 – 25mm thickness minimises added floor height while providing sufficient strength and stability even for heavy stone/porcelain tiles.

Durable & moisture-resistant: Cement construction resists swelling, warping or deterioration — a big advantage over timber-based boards in bathrooms, kitchens, or damp environments.

Efficient heat transfer: High thermal conductivity and low thermal resistance mean heating systems perform efficiently, with even heat distribution across the floor surface.

Flexible for wet or dry installations: Suitable for both wet (screeded) underfloor heating systems — where you embed pipes — and dry overlay systems (over insulation boards), giving flexibility depending on project type.

Saves installation time and reduces complexity: Interlocking edges (in many models) mean no screws, straightforward fitting, and faster installation compared with traditional screed-based floors.

-

Heat Pump Costs & Grants in the UK (2025): What...

Taking time to understand the actual costs, inclusive of grants, upgrades, and running savings, puts you in a strong position

Heat Pump Costs & Grants in the UK (2025): What...

Taking time to understand the actual costs, inclusive of grants, upgrades, and running savings, puts you in a strong position

-

Best Floor Coverings for Water Underfloor Heati...

Make your decision with these principles in mind and you'll enjoy efficient, radiant heat for years to come.

Best Floor Coverings for Water Underfloor Heati...

Make your decision with these principles in mind and you'll enjoy efficient, radiant heat for years to come.

-

Top 5 Underfloor Heating Trends in the UK for 2...

Explore your options and take the next step towards effortless warmth and real savings.

Top 5 Underfloor Heating Trends in the UK for 2...

Explore your options and take the next step towards effortless warmth and real savings.

-

Top 5 Signs of a Reliable Trade Underfloor Heat...

Amid this growing opportunity, the difference between a solid partner and a mediocre wholesaler drives not just project outcomes but also business reputations and profit margins.

Top 5 Signs of a Reliable Trade Underfloor Heat...

Amid this growing opportunity, the difference between a solid partner and a mediocre wholesaler drives not just project outcomes but also business reputations and profit margins.